8 12 18 20 26 28 30AWG high temperature PTFE Insulated Wire Manufacturers

About PTFE wire

Polytetrafluoroethylene wires allow wiring systems to be used and operated in the most demanding of environments. PTFE is resistant to lubricants and fuels, very flexible, plus it has excellent thermal and electrical properties.

1. High temperature resistance

2. Cold resistance

3. Good softness

4. Aging resistance

5. Anti-interference

6. Easy insulation stripping

7. Easy welding conductor

8. Small diameter

9. Especially suitable for frequent bending occasions

Applications of PTFE Wire

1. For connecting internal electrical equipment of various kinds of aircraft, airships, armored vehicles, ships under high temperature environment.

2. In industrial and mining enterprises such as metallurgy, petroleum, chemical and power plants, and is used as a connecting line for various electrical appliances, instruments and automatic devices under high temperature conditions and harsh environments

Properties of PTFE Wire

1. Rated voltage: 125V, 300V, 600V

2. Working temperature: -60 ~ +250 ° C, short-term temperature can be 350 ° C

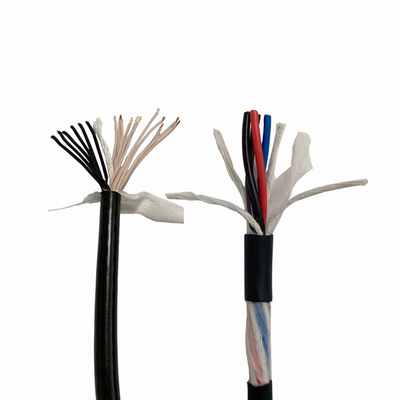

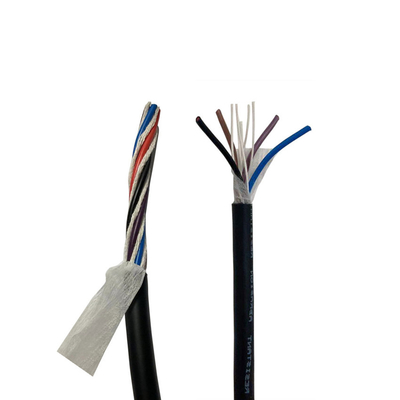

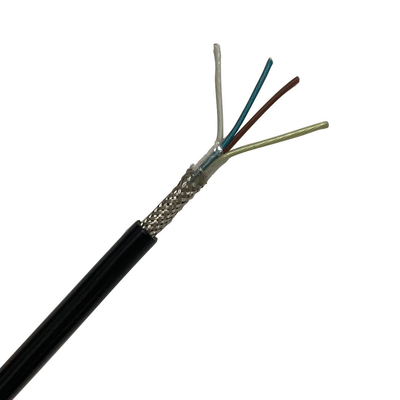

3. Conductor: bare copper wire, silver plated copper wire or nickel-plated copper wire

4. Insulation: PTFE film (polytetrafluoroethylene film wrapped insulation) or add braided shield and sheath.

5. Color: Red,Yellow,Green,Brown,Transparent,Grey,Blue,Orange,White,Black etc.

| Wire gauge |

Cross-section

area

|

Conductor

structure

|

Max.OD of wire

mm |

Reference weight

kg/km |

| AF |

AFP |

AFPF |

AF |

AFP |

AFPF |

| AF-1 |

AFP-1 |

AFRPF-200 |

AF-1 |

AFP-1 |

AFRPF-200 |

| AFR-200 |

AFRP-200 |

AFRPF-250 |

AFR-200 |

AFRP-200 |

AFRPF-250 |

| AWG |

mm2 |

mm |

AFR-250 |

AFRP-250 |

|

AFR-250 |

AFRP-250 |

| 36AWG |

0.013 |

7/0.05 |

0.57 |

0.97 |

1.45 |

0.44 |

1.89 |

2.93 |

| 32AWG |

0.035 |

7/0.08 |

0.67 |

1.15 |

1.55 |

0.73 |

2.39 |

3.52 |

| - |

0.05 |

10/0.08 |

0.72 |

1.28 |

1.68 |

0.91 |

2.67 |

3.85 |

| - |

0.07 |

14/0.08 |

0.75 |

1.3 |

1.7 |

1.16 |

3.05 |

4.29 |

| - |

0.1 |

21/0.08 |

0.85 |

1.4 |

1.8 |

1.57 |

3.63 |

4.95 |

| 26AWG |

0.12 |

24/0.08 |

0.85 |

1.5 |

1.9 |

1.66 |

4.18 |

5.45 |

| - |

0.14/0.15 |

30/0.08 |

0.9 |

1.55 |

1.95 |

2.07 |

4.32 |

5.72 |

| - |

0.2 |

42/0.08 |

1 |

1.65 |

2 |

2.72 |

5.17 |

6.67 |

| - |

0.25 |

56/0.08 |

1.1 |

1.7 |

2.05 |

3.47 |

6.13 |

7.73 |

| 22AWG |

0.3 |

62/0.08 |

1.18 |

1.75 |

2.25 |

4.2 |

7.55 |

9.3 |

| - |

0.35 |

75/0.08 |

1.2 |

1.8 |

2.35 |

4.7 |

7.74 |

10.2 |

| 20AWG |

0.5 |

63/0.1 |

1.45 |

2.05 |

2.4 |

5.36 |

8.54 |

11 |

| - |

0.75/0.80 |

91/0.1 |

1.69 |

2.39 |

/ |

8.19 |

11.9 |

/ |

| 18AWG |

1 |

56/0.15 |

1.95 |

2.5 |

/ |

10.9 |

15.2 |

/ |

Noted:Specification and core no. are not limited to above regulation,they could be customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!