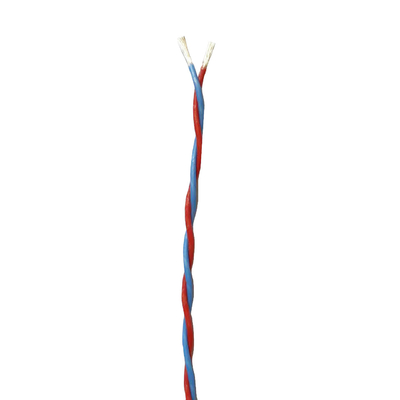

high temperature Insulated Twisted Pair Silver Plated PTFE Hook Up Wire

About PTFE wire

It has excellent corrosion resistance, oil resistance, strong acid, strong alkali resistance, strong oxidant, etc. Excellent electrical insulation performance, high voltage resistance, low loss at high frequency, no moisture absorption, large insulation resistance; It has excellent fire resistance, aging resistance and long service life.

Applications of PTFE Wire

1. In the electronic industry, can be used for temperature compensation wire, low temperature resistance wire, high temperature heating wire, aging resistance wire and flame retardant wire;

2. In household appliance industry, it can be used for internal wiring of air conditioner, microwave oven, electronic disinfection cabinet, electric rice fort, electronic hot water bottle, electric heater, electric oven, electric frying pan, lamps and lanterns, etc.

Properties of PTFE Wire

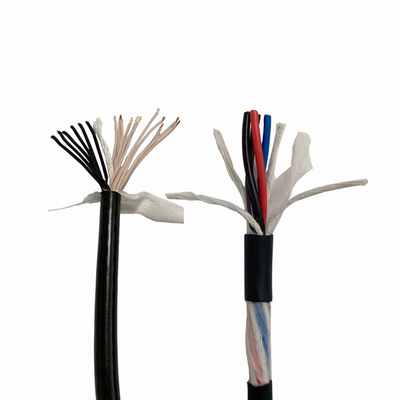

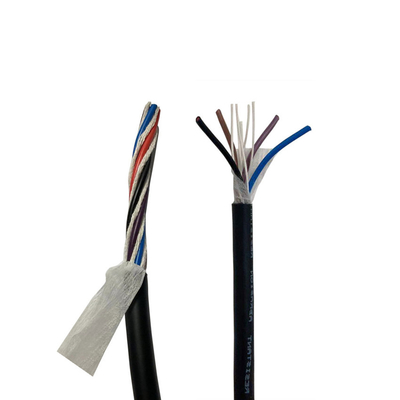

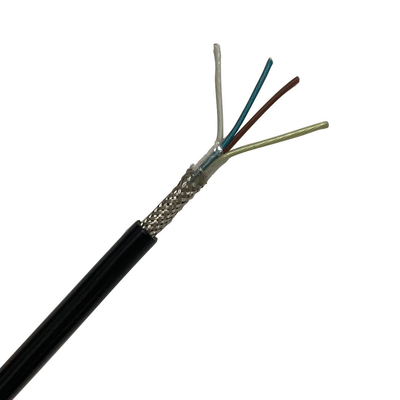

1. The conductor is made of 0.03-0.08mm copper wire or silver-plated copper wire wrapped by ptfe film

2. Core can be made: 1, 7, 19, 30, 42, 49, 75, 100

3. Color: black, brown, red, orange, yellow, green, blue, purple, gray, white

4. Long-term working temperature: copper core -60 ~ +200℃, silver-plated copper core -60 ~ +250℃

| Conductor |

Insulation thickness

mm |

Wire outer diameter

mm |

Resistance of insualtion |

Nominal section area

mm2 |

single wire x dia. |

Conductor Dia.

mm |

110V |

250V |

600V |

AFR-250 type |

AFRP-250 type |

MΩ·km |

| mm |

110V |

250V |

600V |

110V |

250V |

600V |

|

| 0.013 |

7×0.05 |

0.15 |

0.1 |

0.15 |

0.25 |

0.38 |

0.49 |

0.71 |

0.7 |

0.82 |

1.02 |

5×103 |

| 0.035 |

7×0.08 |

0.24 |

0.1 |

0.15 |

0.25 |

0.47 |

0.58 |

0.81 |

0.85 |

0.91 |

1.14 |

| 0.06 |

7×0.10 |

0.3 |

0.1 |

0.15 |

0.25 |

0.55 |

0.65 |

0.87 |

0.9 |

0.97 |

1.2 |

| 0.08 |

7×0.12 |

0.36 |

0.1 |

0.15 |

0.25 |

0.6 |

0.7 |

0.93 |

1 |

1.03 |

1.26 |

| 19×0.07 |

| 0.1 |

7×0.14 |

0.42 |

0.1 |

0.15 |

0.25 |

0.7 |

0.83 |

1 |

1.05 |

1.15 |

1.3 |

| 19×0.08 |

| 0.14 |

7×0.16 |

0.5 |

0.1 |

0.15 |

0.25 |

0.73 |

0.85 |

1.05 |

1.05 |

1.18 |

1.45 |

| 19×0.10 |

| 0.2 |

7×0.20 |

0.6 |

|

0.15 |

0.3 |

0.85 |

0.97 |

1.3 |

1.3 |

1.4 |

1.7 |

| 19×0.12 |

| 0.35 |

7×0.25 |

0.8 |

|

0.15 |

0.3 |

|

1.2 |

1.5 |

|

1.6 |

1.9 |

| 19×0.16 |

| 0.5 |

7×0.30 |

0.9 |

|

0.15 |

0.3 |

|

1.3 |

1.6 |

|

1.7 |

2 |

| 19×0.18 |

| 0.8 |

7×0.37 |

1.1 |

|

0.2 |

0.3 |

|

1.65 |

1.85 |

|

2.05 |

2.3 |

| 19×0.23 |

| 1 |

19×0.26 |

1.3 |

|

0.2 |

0.3 |

|

1.88 |

2 |

|

2.25 |

2.45 |

| 1.2 |

19×0.28 |

1.4 |

|

0.2 |

0.3 |

|

1.95 |

2.15 |

|

2.38 |

2.55 |

| 1.5 |

19×0.32 |

1.6 |

|

0.2 |

0.3 |

|

2.15 |

2.35 |

|

2.63 |

2.83 |

| 2 |

19×0.37 |

1.85 |

|

0.2 |

0.3 |

|

2.4 |

2.6 |

|

2.97 |

3.08 |

| 2.5 |

19×0.14 |

2.34 |

|

0.2 |

0.35 |

|

|

2.95 |

|

3.2 |

3.43 |

| 49×0.26 |

| 3 |

49×0.28 |

2.52 |

|

0.2 |

0.35 |

|

|

3.1 |

|

3.37 |

3.5 |

| 4 |

49×0.32 |

2.88 |

|

|

0.35 |

|

|

3.52 |

|

|

4.12 |

| 6 |

49×0.39 |

3.51 |

|

|

0.35 |

|

|

4.15 |

|

|

4.75 |

Noted:Specification and core no. are not limited to above regulation,they could be customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!