600V Heat Abrasion Resistant 14 18 16 AWG PTFE high temperature Insulation Wire

About PTFE wire

PTFE wires allow wiring systems to be used and operated in the most demanding of environments. PTFE is resistant to lubricants and fuels, very flexible, plus it has excellent thermal and electrical properties

Application:

Internal wiring for electronic equipment and small electrical equipment; Used for Oil equipment, Electric machinery, Automotive cables, Outdoor lighting, PTC thermistors, Electric components etc.

Features:

It has excellent corrosion resistance, oil resistance, strong acid, strong alkali resistance, strong oxidant, etc. Excellent electrical insulation performance, high voltage resistance, low loss at high frequency, no moisture absorption, large insulation resistance; It has excellent fire resistance, aging resistance and long service life.

Properties:

1. Rated voltage: 600V or Below

2. Long-term working temperature: copper core -60 ~ +200℃, silver-plated copper core -60 ~ +250℃

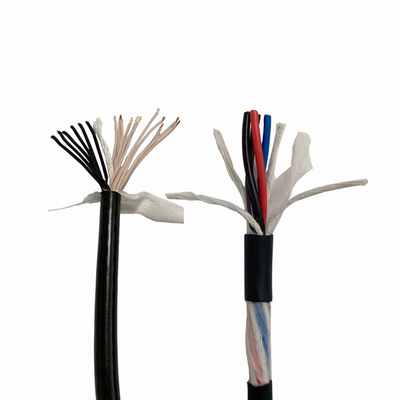

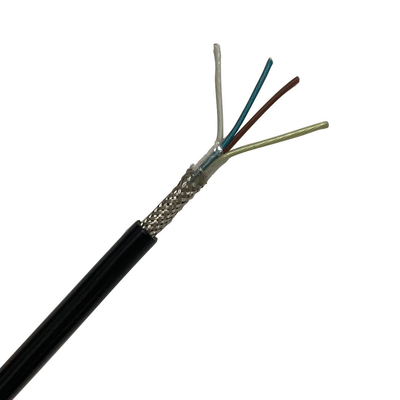

3. Conductor: Bare copper stranded, Silver plated copper stranded

4. Insulation: high temperature Ptfe insulated

5. Available Colors: White/ Blue/ Red/ Yellow/ Black/ Brown/ Gray/ Violet...

6. Core can be made: 1, 7, 19, 30, 42, 49, 75, 100

7. Test voltage: 1000V, 1500V, 2500V

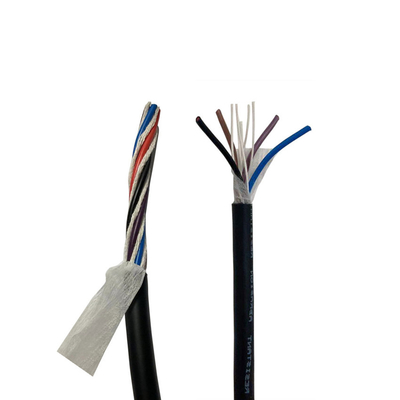

| Silver coated copper conductor PTFE insulation lead wire |

| Silver coated copper conductor PTFE insulation shield lead wire |

| Silver coated stranded copper conductor PTFE insulation shield lead wire |

| Silver coated stranded copper conductor PTFE insulation twisted shield lead wire |

|

Nominal Section

(mm2)

|

Conductor

Construction

(No/mm)

|

Insulation Thickness

(mm)

|

Outer Diameter

(mm)

|

D.C. conductor resistance at

20ºC(Ω/km)

|

| Tinned copper |

Silver coated copper |

| 0.05 |

10/0.08 |

0.3 |

0.9 |

383 |

370 |

| 0.06 |

7/0.10 |

0.3 |

0.9 |

348 |

339 |

| 0.08 |

7/0.12 |

0.3 |

0.96 |

286 |

280 |

| 0.1 |

7/0.14 |

0.3 |

1.02 |

157 |

150 |

| 0.12 |

7/0.15

30/0.07

|

0.3 |

1.05 |

152 |

145 |

| 0.14 |

7/0.16

19/0.10

|

0.3 |

1.08 |

136 |

130 |

| 0.15 |

30/0.08 |

0.3 |

1.1 |

111 |

105 |

| 0.2 |

7/0.02

19/0.12

|

0.3 |

1.2 |

87 |

82 |

| 0.35 |

19/0.16 |

0.3 |

1.4 |

57 |

54 |

| 0.5 |

19/0.18 |

0.3 |

1.5 |

40 |

37.5 |

| 0.8 |

19/0.23 |

0.32 |

1.79 |

24 |

23 |

| 1 |

19/0.26 |

0.35 |

2 |

21 |

20 |

| 1.2 |

19/0.28 |

0.45 |

2.3 |

19 |

18 |

| 1.5 |

19/0.32 |

0.45 |

2.5 |

13 |

12 |

| 2 |

19/0.37 |

0.45 |

2.75 |

10 |

9 |

| 2.5 |

37/0.30 |

0.55 |

3.2 |

8 |

7 |

| 3 |

37/0.32 |

0.68 |

3.6 |

6.8 |

6.4 |

Noted: Specification and core no. are not limited to above regulation, they could be customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!