19 Strands Tinned Copper Fep Electirc Wire

What is FEP electric wire?

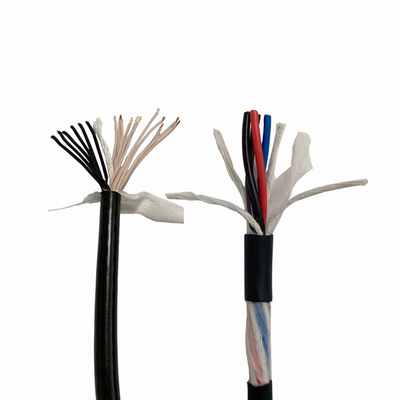

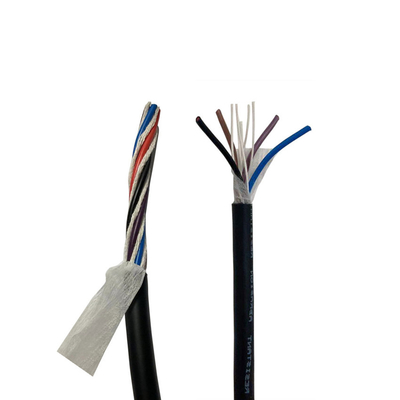

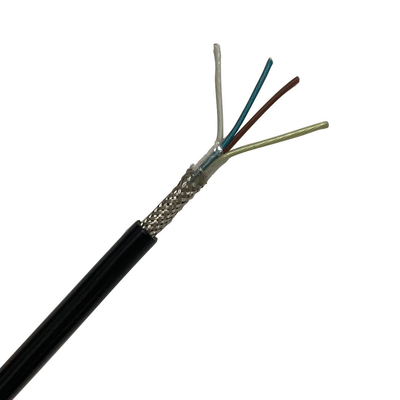

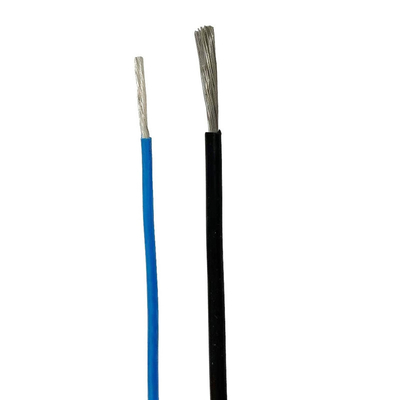

FEP wire is fluoroplastic insulated wire which extruded and covered with FEP resin over tin coated annealed copper wire,silver plated annealed copper etc.

The FEP electric wire has excellent corrosion resistance, almost insoluble in any organic solvent, oil resistance, strong acid resistance, strong alkali resistance, strong oxidizing agent, etc.; excellent electrical insulation performance, high voltage resistance, low frequency loss, no moisture absorption, insulation Large resistance; excellent non-combustible, non-aging performance, oxygen index ≥ 90, long service life.

Application of FEP electric wire

The FEP insulated wire suitable for the connection of electrical equipment and instrument under high temperature conditions. Such as aerospace, defense science and technology metallurgical chemical, electric refining, ship roads and other high-tech fields and vehicle manufacturing, video equipment, lighting equipment, baking room drying tunnel.

Properties of FEP electric wire:

1. Rated voltage: AC 600V

2. Working temperature: -65 ~ +200 ° C

3. Conductor type: solid core or stranded

4. Conductor materials:Tin or silver plated copper wire

5. Insulation: FEP Insulation

6. Color: red/yellow/blue/white/black/yellow green /brown etc.

Where To Buy Fep Wire?You can contact SANCO cable anytime.

vicky@sancocable.com

Whatsapp:+86 13100323537

| Wire gauge |

Cross-section area |

Conductor structure |

Max. OD of cable(mm) |

AF-200

AF-200-1 |

AFP-200 |

| AWG |

mm2 |

mm |

250V |

600V |

250V |

600V |

| 36AWG |

0.013mm2 |

7/0.05 |

0.65 |

0.85 |

1.1 |

1.3 |

| 32AWG |

0.035mm2 |

7/0.08 |

0.75 |

0.95 |

1.2 |

1.4 |

| 30AWG |

0.05mm2 |

7/0.10 |

0.85 |

1.05 |

1.35 |

1.6 |

| 28AWG |

0.07mm2 |

7/0.12 |

0.9 |

1.1 |

1.4 |

1.65 |

| - |

0.1mm2 |

7/0.14 |

1 |

1.2 |

1.55 |

1.75 |

| 26AWG |

0.14mm2 |

7/0.16 |

1.1 |

1.3 |

1.65 |

1.95 |

| 24AWG |

0.2mm2 |

19/0.12 |

1.2 |

1.4 |

1.75 |

1.98 |

| - |

0.3mm2 |

7/0.23 |

1.25 |

1.48 |

1.8 |

2.05 |

| 22AWG |

0.35/0.40mm2 |

19/0.16 |

1.4 |

1.6 |

1.95 |

2.2 |

| 20AWG |

0.5mm2 |

19/0.18 |

1.6 |

1.8 |

2.2 |

2.4 |

| - |

0.6mm2 |

19/0.20 |

1.75 |

1.98 |

2.3 |

2.5 |

| - |

0.75/0.80mm2 |

19/0.23 |

1.8 |

2.1 |

2.4 |

2.6 |

| 18AWG |

1mm2 |

19/0.26 |

2 |

2.2 |

2.6 |

2.9 |

| 16AWG |

1.2mm2 |

19/0.28 |

2.2 |

2.4 |

2.8 |

3.1 |

| - |

1.5mm2 |

19/0.32 |

2.4 |

2.6 |

3.1 |

3.3 |

| 14AWG |

2mm2 |

19/0.37 |

2.7 |

2.9 |

3.4 |

3.6 |

| - |

2.5mm2 |

37/0.30 |

3.4 |

3.6 |

4.2 |

4.4 |

| 12AWG |

3mm2 |

37/0.32 |

3.6 |

3.8 |

4.4 |

4.6 |

| - |

4mm2 |

37/0.37 |

4 |

4.2 |

4.8 |

5.1 |

| 10AWG |

5mm2 |

37/0.41 |

4.5 |

4.7 |

5.3 |

5.6 |

| - |

6mm2 |

37/0.45 |

4.8 |

5 |

5.7 |

5.9 |

| 8AWG |

8mm2 |

133/0.28 |

6 |

6.5 |

6.8 |

7.3 |

Noted:Specification and core no. are not limited to above regulation,they could be customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!